Product model: VB-7000

Nominal diameter: DN65~200mm

Nominal pressure: PN1.6MPa

Applicable temperature: 0℃~60℃

Applicable medium: steam, cold water, hot water

Working Principle

The drive is driven by a reversible synchronous motor with a magnetic clutch. The motor can generate stable torque under the condition of standstill through the magnetic effect of the motor rotor and the clutch. Therefore, when there is no current passing through the motor, it can stably stop at any point. When the valve is fully opened or fully closed, the magnetic clutch is disengaged and the adjustment is stopped. Signals from the drive's incremental or proportional controller can turn the motor clockwise or counter-clockwise.

Product Features

Synchronous reversible motor with 24V AC voltage. 1000 Newton force. Limit magnetic clutch. The action is transmitted by gears, the output gear screw group adopts a plane rolling bearing that rotates around the central axis, and the valve shaft adopts a central screw pipe and a positioning disc. Valve position indicator. Fire-resistant ABS plastic cover. A manual lever can be attached. Easy to install on site. Suitable for straight stroke control valves under 23mm.

1. The actuator adopts cast aluminum bracket and plastic shell, which is small in size and light in weight.

2. The permanent magnet synchronous motor is selected, and it has a hysteresis clutch mechanism, which has a reliable self-protection function.

3. Suitable for various control signals: increment (floating point), voltage (0~10V), current (4~20mA).

4. With 0~10V or 4~20mA feedback signal (optional).

5. The transmission gear adopts metal gear, which greatly improves the service life of the driver.

6. Low power consumption, large output force and low noise.

7. The valve body is available in cast copper, cast iron and ductile iron to suit the requirements of different working media and temperatures.

8. The valve body has two types of threaded connection and flange connection, which is easy to install.

9. The structure of the valve body includes: two-way valve (single seat) and two-way balance valve (balanced).

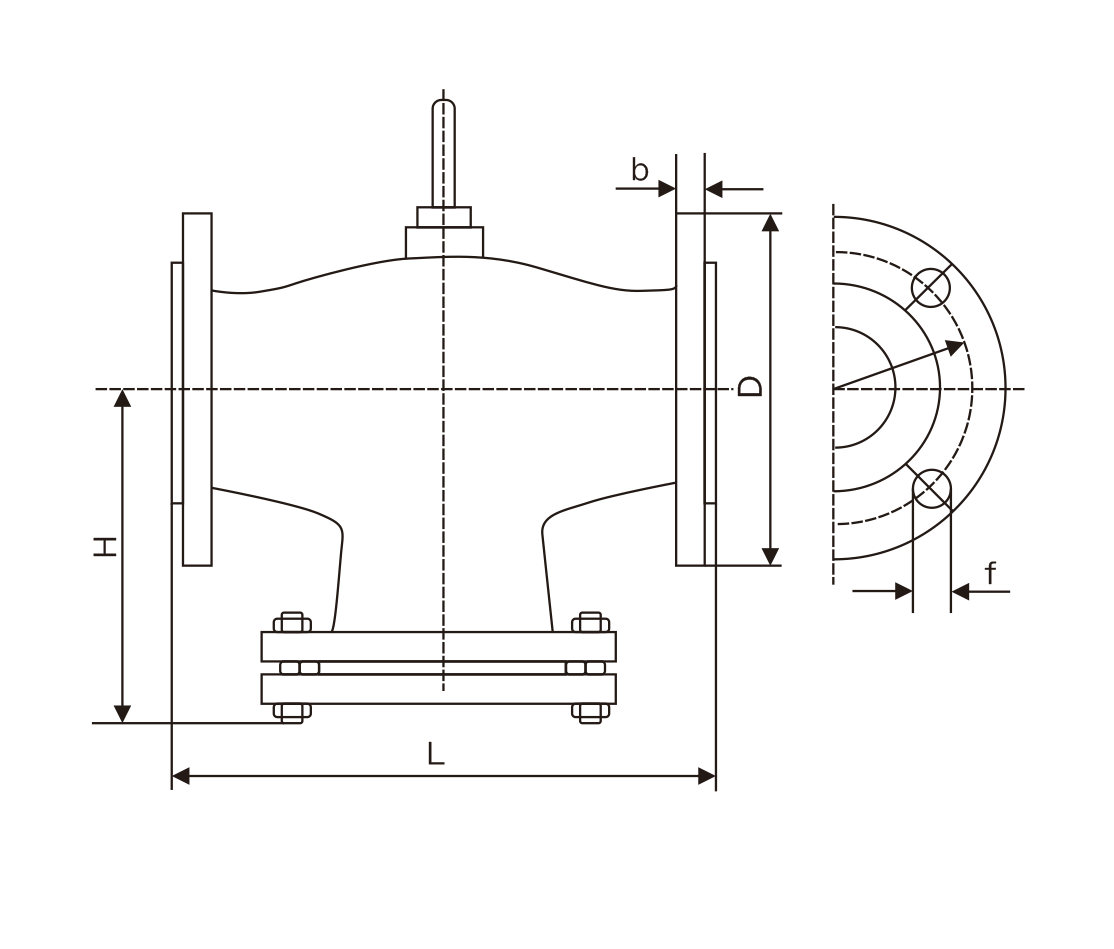

Main External Connection Dimensions

| Specification | L | H | H1 | D | C | K | n-d | Differential pressure KPa | WT(kg) | L |

| DN65 | 290 | 158 | 150 | 185 | 20 | 145 | 4-18 | 400 | 23 | 45 |

| DN80 | 310 | 195 | 185 | 200 | 20 | 160 | 8-18 | 400 | 31 | 45 |

| DN100 | 350 | 216 | 205 | 220 | 20 | 180 | 8-18 | 300 | 39 | 45 |

| DN125 | 400 | 237 | 230 | 250 | 22 | 210 | 8-18 | 200 | 66 | 45 |

| DN150 | 480 | 282 | 280 | 285 | 22 | 240 | 8-22 | 100 | 87 | 45 |

| DN200 | 533 | 289 | 340 | 340 | 30 | 295 | 12-22 | 100 | 90 | 45 |