Item model number: J41W

Nominal diameter: DN15-DN400mm

Nominal pressure: PN1.6MPa-32MPa

Applicable medium: water, oil, gas

Applicable temperature: -20℃-425℃

Body Material: Stainless Steel

Product Structure Features

Stainless steel globe valve are used to cut or connect the pipe medium in Class150~2500 and working temperatures ≤600℃,in oil & chemial industry,thermal power station.

The main structure features include

1.The products designs are in accordance with the ANSI B16.34 and BS 1873,with rationaI structure reliable seal ,excellent performance,and pretty appearance.

2.Co-radix alloy welded sealing surface,anti-wearing,erosion-proof abrasion-proof and longer use life.

3.The surface and the adjusting media of the valve shaft are nitrogenized so that it is erosion and abrasion resistant.

4.The central cavity with pressures ≥Class1500 adopts self-tightening sealing structure,which means that the sealing rise with the internal pressure,and sealing is highly reliable.

5.There is backward sealing structure in the valve,so the sealing is reliable.

6.The material of the parts and the flange sizes can be chose and matched according to the applications and the requirements of the users.That can satisfies all kinds of working requirements.

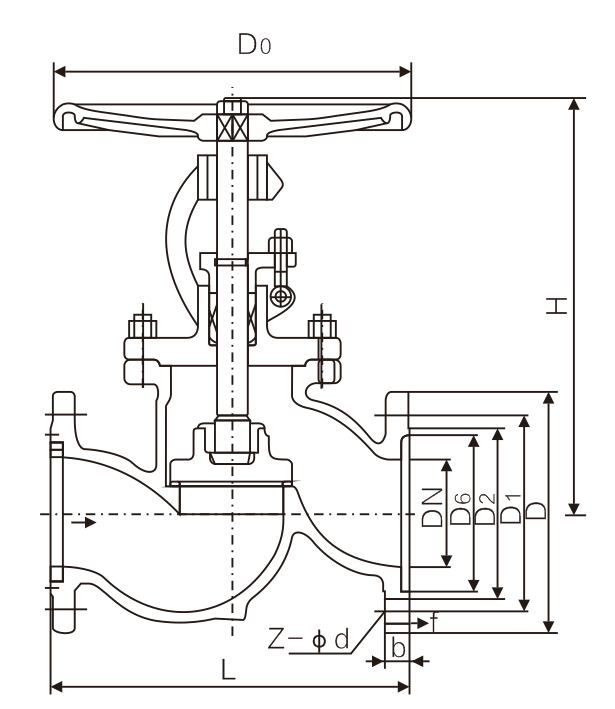

Main external connection dimensions and weight(PN1.6MPa)

| DN | L | D | D1 | D2 | b | n-Φd | H | D0 |

| 10 | 130 | 90 | 60 | 40 | 14 | 4-Φ14 | 198 | 120 |

| 15 | 130 | 95 | 65 | 45 | 14 | 4-Φ14 | 218 | 120 |

| 20 | 150 | 105 | 75 | 55 | 14 | 4-Φ14 | 258 | 140 |

| 25 | 160 | 115 | 85 | 65 | 14 | 4-Φ14 | 275 | 140 |

| 32 | 180 | 135 | 100 | 78 | 16 | 4-Φ18 | 280 | 160 |

| 40 | 200 | 145 | 110 | 85 | 16 | 4-Φ18 | 330 | 180 |

| 50 | 230 | 160 | 125 | 100 | 16 | 4-Φ18 | 350 | 200 |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-Φ18 | 370 | 280 |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-Φ18 | 400 | 280 |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-Φ18 | 415 | 320 |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-Φ18 | 460 | 360 |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-Φ23 | 510 | 450 |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-Φ23 | 710 | 500 |

| 250 | 650 | 405 | 335 | 320 | 30 | 12-Φ25 | 786 | 550 |

| 300 | 750 | 460 | 410 | 375 | 30 | 12-Φ25 | 925 | 600 |